The aim of the project is to integrate an active element into a bolted connection that additionally secures the bolted connection in particularly critical applications. The advantages of the screw connection, such as loosenability and cost efficiency, are to be retained. In the project, the Chair of Applied Laser Technologies (LAT) is working together with partners from industry and research.

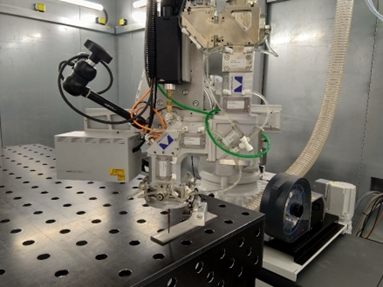

The tests are carried out at the LAT using a robot-based system. The focus here is on selecting the process parameters that are suitable for the desired function of the component. The layer-substrate connections created by Laser Metal Deposition are analysed metallographically. Another field of activity is laser-based modification through localised heat treatment of the components. In addition, the surface quality is optimised by laser polishing or mechanical processing.

Project Partner

Term: May 2024 to April 2027